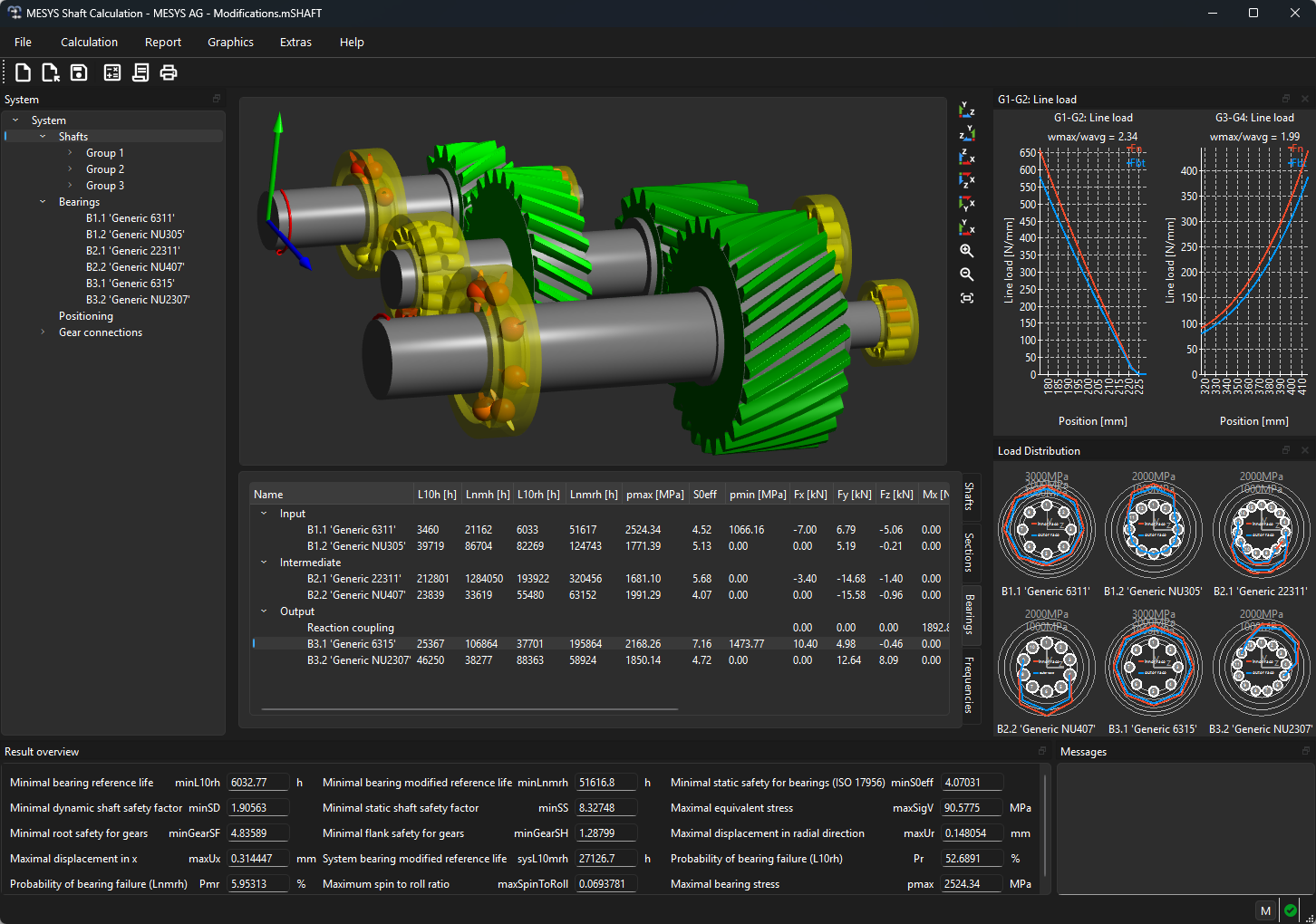

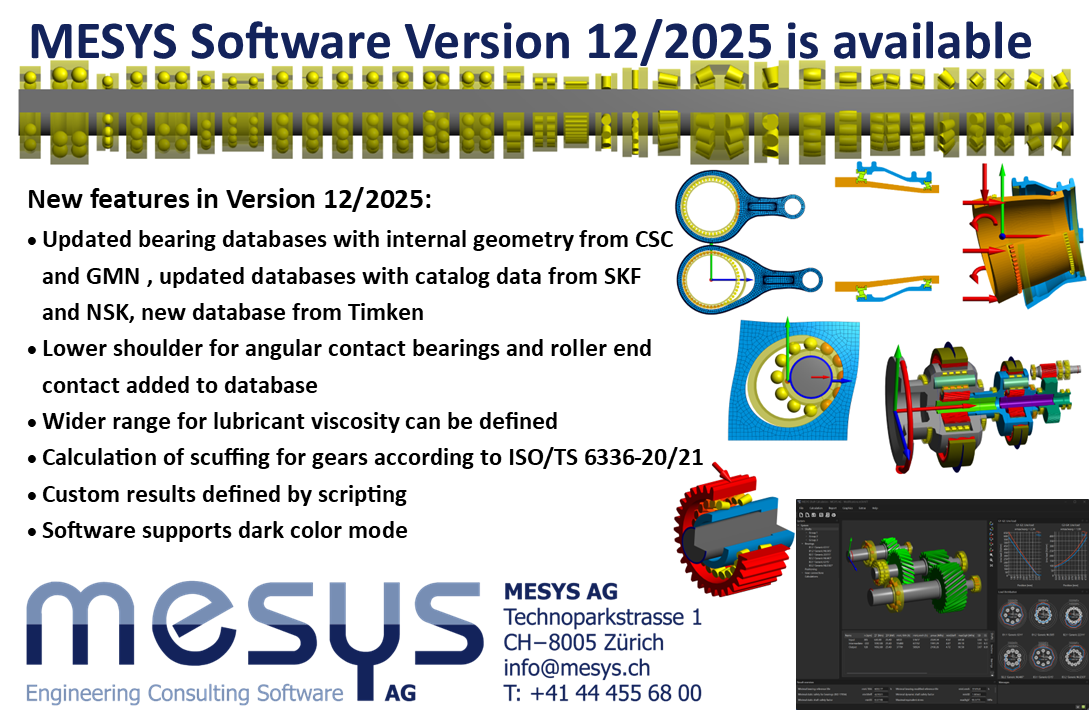

A new version of the MESYS shaft and rolling bearing analysis software including new functionality is available. The bearing analysis software allows the calculation of the load distribution within the bearing as well as bearing life according to ISO 16281. It is integrated in a shaft system calculation offering additional capabilities such as modal analysis, strength calculation for shafts and interfaces to gear calculations. Currently the software is used by customers in 32 countries across 4 continents. The new version is now available under Downloads.

General Extensions

The bearing databases including internal geometry from CSC and GMN are updated. They now include information about the lower shoulder and preloads. The database from HQW/Barden also containing internal geometry is unchanged. Additional encrypted databases containing internal geometry are available from IBC, SLF and GRW, but have to be requested from the manufacturer.

Bearing databases with catalog data from NSK and SKF are updated and a new database from Timken was added.

The lubricant database now supports the definition of viscosities for up to four temperatures. This improves the definition of low or high temperature lubricants.

The appearance of the program can now be adjusted using different styles or font sizes directly in the software instead of configuration files. A dark mode is supported too.

The possibility of defining custom results values was added. This leads to additional possibilities for optimization targets in parameter variations.

Extensions in the Bearing Calculation

For ball bearings a reduction of clearance due to the lubricant film can optionally be considered. The bearing mass (without cage) is calculated and reported.

For angular contact ball bearings, the lower shoulder can be defined now, before it was set automatically by the software. For four-point bearings optionally contact angles for both rings can be defined to consider effects of tolerances.

Extensions in the Shaft Calculation

In the shaft calculation the deflection curves can be shown relative to another part. This allows a better evaluation of clearances between parts as the thermal expansion can be eliminated.

In the 2D-views an option grid and global markers lead to easier estimations of distances.

For cylindrical gear connections additional options for the sizing of profile shift are added and the safety against scuffing is added to result overviews.

The automatic meshing of 3D-FEA based components based on STEP import was improved.

Extensions in the Cylindrical Gear Calculation

The cylindrical gear pair calculation now also calculates scuffing according to ISO/TS 6336-20/21. In addition to the safety for root and flank strength, the safety for scuffing based on flash and integral temperature is shown.

The display of some graphics was improved.