A new version of the MESYS shaft and rolling bearing analysis software including new functionality is available. The bearing analysis software allows the calculation of the load distribution within the bearing and bearing life according to ISO/TS 16281 and it is integrated in a shaft system calculation with additional possibilities like modal analysis, strength calculation for shafts and interfaces to gear calculations. Currently the software is used by customers in 30 countries on 4 continents. The new version is now available under Downloads.

General Extensions

Some start parameters were added to allow an easier integration with other systems. Using the COM-Interface now the parameter calculation can be called to generate additional results. The default for the Help system was set to an external viewer, which can also be started from network drives. Custom formulas can now be used within the parameter variations.

Extensions in the Bearing Calculation

The bearing databases with catalog data from Schaeffler and SKF were updated. Schaeffler provides the number and dimensions of rolling elements and the database has to be provided in encrypted format with hidden internal geometry. For the SKF database the dimensions of the rolling elements are still approximated. The detail geometry like curvatures or profiles are still approximated in both cases.

Regarding the bearing databases including internal geometry, the databases from CSC and HQW/Barden are unchanged from last version. On request additional databases are available from some bearing manufacturers, for example from GMN or IBC.

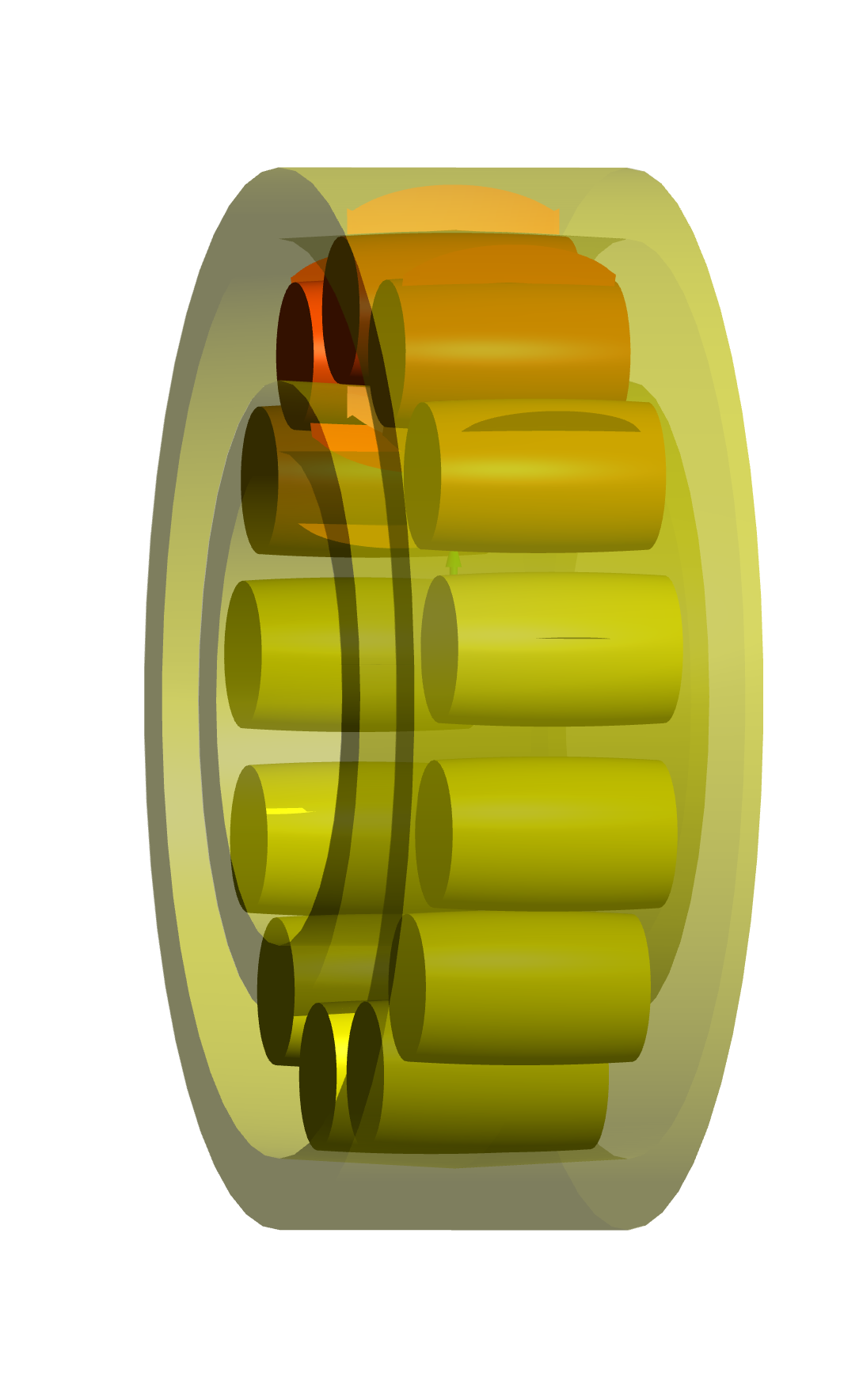

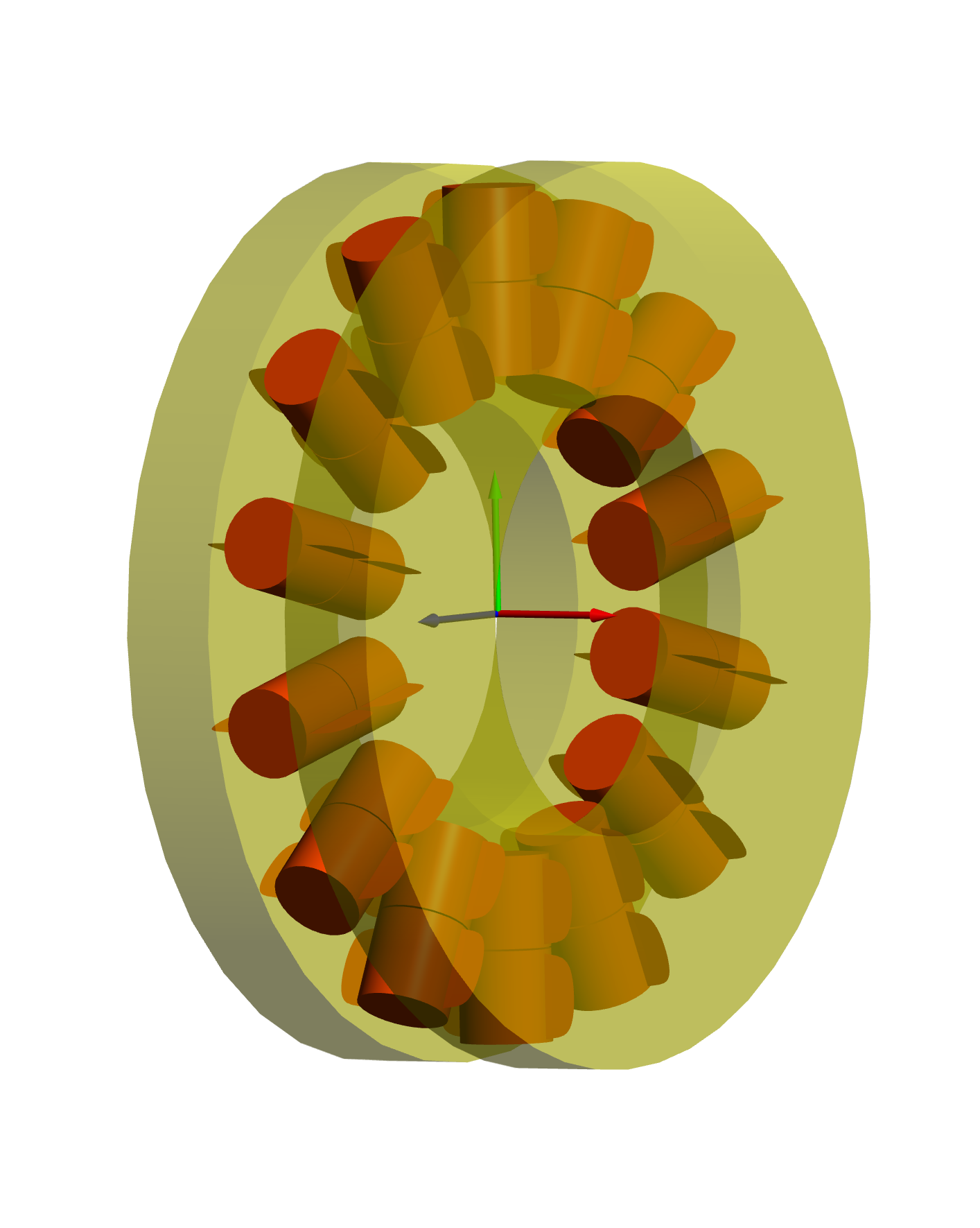

As new bearing types toroidal roller bearings and double row thrust cylindrical roller bearings were added. In contract to barrel roller bearings, toroidal roller bearings have no shoulders and allow larger axial displacements. The radial clearance is dependent on axial displacements. The double row thrust cylindrical roller bearings have the same roller dimensions for both rows.

The track roller calculation with elastic outer ring is now also supported for double row deep groove ball bearings. Before a configuration of two single row bearings had to be used.

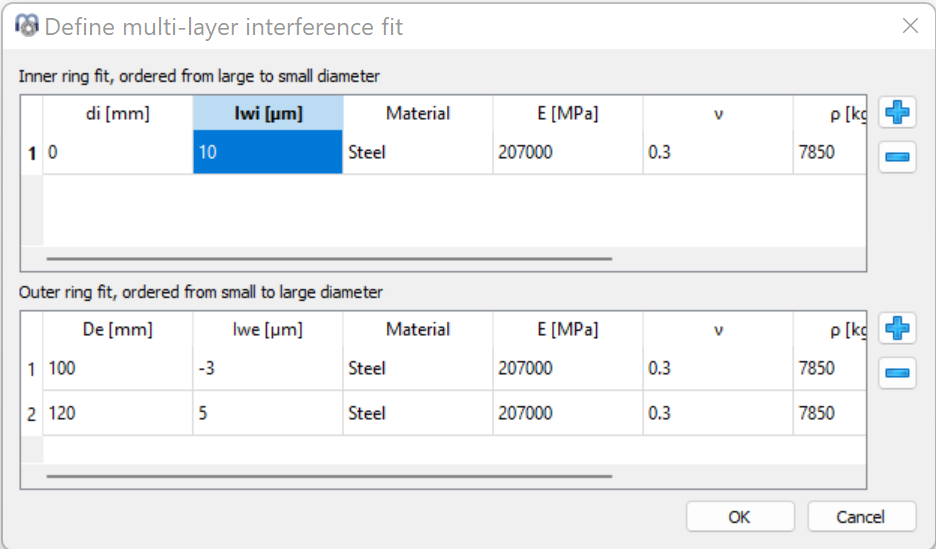

Interference fits affect the operating clearance of bearings. As there had been some customer requests now also multi-layer interference fits can be defined. For the inner and outer ring fit several layers using different materials can now be defined. Influence of centrifugal forces and temperature is considered. The stresses and displacements in the fits can be shown in a diagram.

In addition to stiffness matrices now also compliance matrices are provided in the report and in result tables.

Extensions in the Shaft Calculation

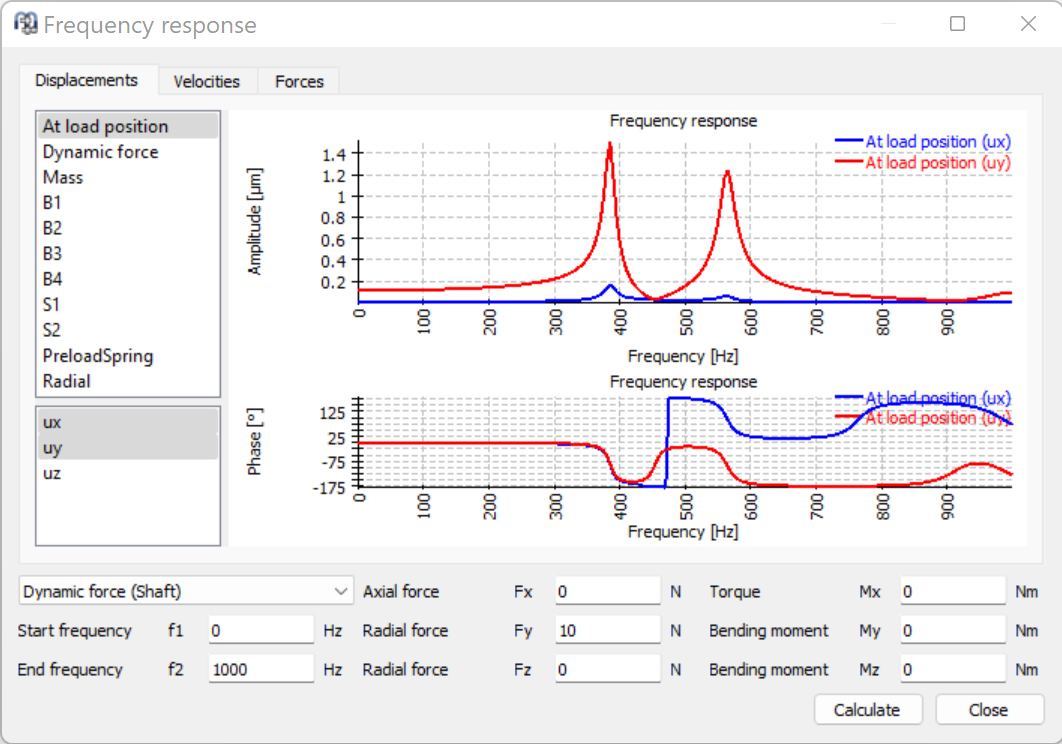

For the calculation of frequency response, a new dialog was added. It allows to calculate the response to periodic excitations in a frequency range and shows the resulting displacements, velocities or forces for several locations in one diagram. In addition to the amplitudes also the phase is shown.

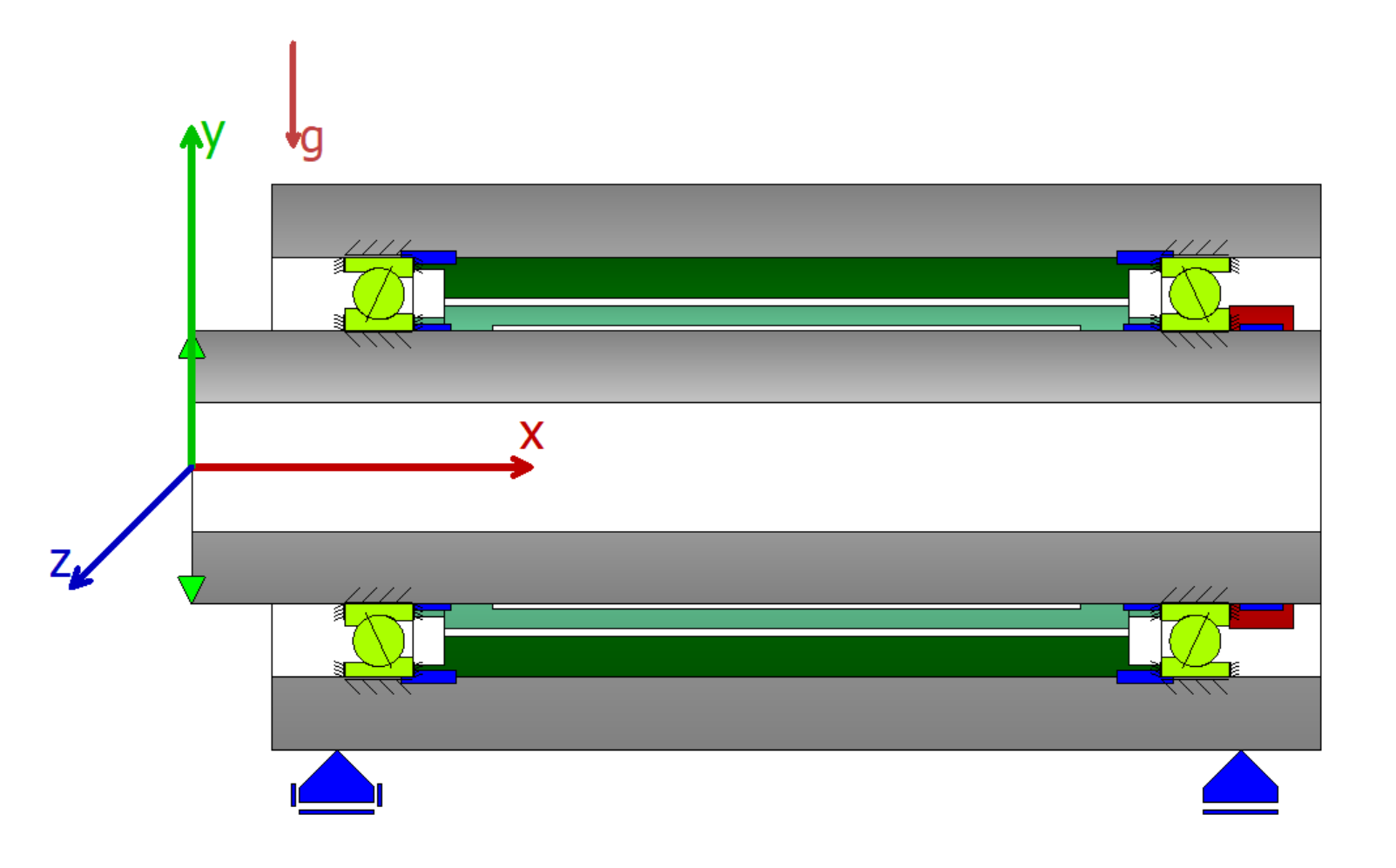

An extended calculation model for bearings allows to specify three contacts for each bearing ring. The bearing ring can be connected to one parts radially and to one part on each axial contact. Clearance between bearing ring and shaft or housing is considered automatically if the fitting is defined for the bearing. For example this allows to define a pretension with a nut directly (nut is shown in red and spacers in green). This leads to tension in the inner shaft and to pressure in the spacers.

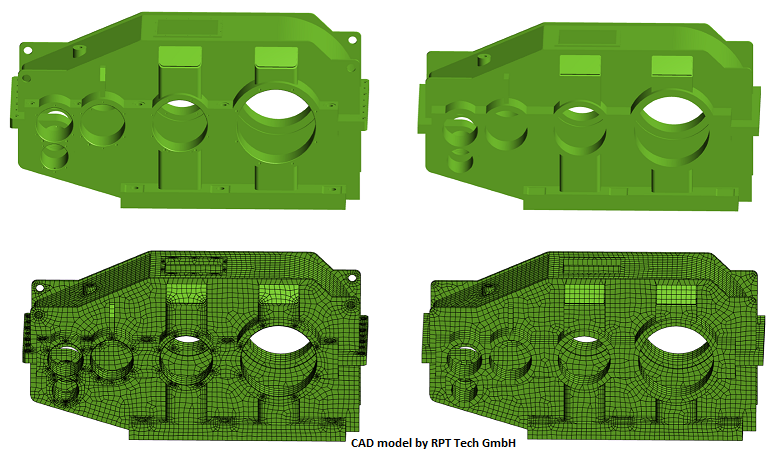

For 3D-elastic parts a new import library is used for STEP import. This allows to do some defeaturing on import. By removing chamfers, radii and small bores, the number of elements can be reduced and therefore reduction time and memory usage.

For 3D-elastic shafts now also orthotropic material can be defined in cartesian coordinates in addition to cylindrical coordinates as before.

Extensions in the Ball Screw Calculation

Several diagrams are added to the ball screw calculation which already had been available in the bearing calculation. So, diagrams for contact stress and sliding speed or wear parameters had been added.